A KEY SUCCESS STORY OF EXPANDER STABILIZER AND SUSPENSION PINS IN MINING

When Expander was relatively new in the mining and minerals industry, a coal mine operator in Wyoming’s Powder River Basin agreed to a trial installation of the brand’s pivot pins for one of its CAT 793B trucks. The results have become a critical example in proving the Expander System’s superiority as an after-market replacement for heavy-duty mining equipment.

In 2008, Expander still had ground to gain in both the mining industry and the United States. But that year, the company teamed up with KEC Wyoming, a major distributor of off-road equipment, to help address maintenance issues that were affecting a KEC customer’s fleet of mining trucks.

The 50 Caterpillar 793B trucks were crucial to a coal mining operation in the Powder River Basin. Considered to be the most prolific coal field in the world, the Basin was then in the midst of its most prolific period of coal mining. More coal would be produced in Wyoming that year than in any other before or since (according to the state’s geological survey). Yet the customer was struggling with prolonged downtimes for the trucks it used to haul coal. Worn and damaged lug-ear bores had made replacing their trucks’ stabilizer and suspension pins so time-consuming that concerns were growing about the impact on the operation’s bottom line.

The Expander System, with its quick and easy installation and dramatic extension of stabilizer and suspension pin life-cycles, offered a solution ideally matched for the challenge.

“It’s a perfect example of where the Expander System shines.”

According to Nicholas Addington, Global Mining Segment Manager for the Nord-Lock Group in the US, it’s an Expander case study that’s still shared with those in the mining sector to this day.

“It’s a perfect example of where the Expander System shines,” Addington explains. “The CAT 793s are some of the most used mining trucks in the world, and it highlights pretty much all the benefits of using Expander.

The issues with the stabilizer and suspension pins for the customer’s fleet of CAT 793B trucks aren’t unique in mining. Heavy-duty trucks and equipment are designed to carry massive loads across harsh and rough terrain, but there’s often contact between pivot pins and parent metal within the machine that can seriously wear the lug-ear bores.

For the KEC Wyoming customer, there was a particular amount of such wear and damage to the bores for the rear stabilizer pins, which Addington explains is fairly common for haul trucks in mining. And conventional repair methods require corrective welding and line boring before installing new pins, during which the truck is completely out of service.

“If the machine's down because they’re doing lots of repairs, that lowers their productivity,” says Addington. “Then line boring is costly and takes time. So it's a huge expense to repair.”

Easy installation and maintenance

The customer agreed to give KEC and Expander an on-site field test. The short demonstration allowed them to see for themselves the process of installing the Expander System into one of their CAT 793B trucks.

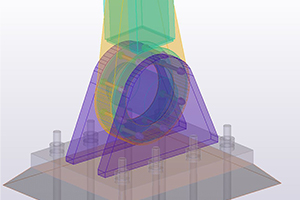

As Addington explains, there was no need for welding and line boring since Expander pins are installed directly into the mounting’s worn lug bores. “Because it's tapered, the Expander System can easily align to the hole,” he says. “It's essentially self-aligning everything, and your press length distances are cut in half. So it's much faster and easier to install.”

The field test was also an opportunity to witness firsthand how the Expander System prevents further damage. When the expansion sleeves conform to the wear pattern of the lug ears, leaving no clearance between the bore hole and the pin, and locking the system in place. This prevents the pivot joints from exhibiting play that creates wear in the lug bores.

It wasn’t long before the Expander System was a standard repair for the customer’s fleet, and all 50 trucks were eventually outfitted with Expander pins. The change resulted in dramatic savings through reduced maintenance costs and equipment downtime.

“It's a proven value-added solution that saves customers time and money.”

More than 15 years later, the customer case study for the Expander System and the CAT 793B trucks in the Powder River Basin still resonates with those in the mining and minerals sector.

According to Addington, it’s been key to convincing other mining operations to utilize Expander pins as after-market replacements in their haul trucks, excavators, dozers, and more. And the successful applications have spread over the years throughout the US and Canada, as well as South America, Australia, and Africa.

“These are global issues for all mines, and this example just encompasses what it is about Expander that helps the customers, how it truly works and has been working for years,” says Addington. “It's a proven value-added solution that saves customers time and money.”